Because of its strength, unique density and corrosion resistance, titanium has found applications in many industries. For high quality tubing products, it’s often a better substance to use than competing materials like stainless steels or super alloys

The density of titanium is about 60 per cent of that of steel- or nickel-based alloys giving significant weight savings in aerospace structures. The tensile strength is better than that of austenitic or ferritic stainless steels. Titanium is exceptionally corrosion resistant and exceeds the resistance of stainless steels in most environments. The metal is non-magnetic too, and has good heat transfer properties, with a melting point higher than steel alloys

1.General Information

Item name | Titanium tubing |

Standard | ASTM B337, ASTM B338, ASTM B861, ASTM B862 |

Grade | Gr1, Gr2, Gr9, Gr11, Gr12, Gr16, Gr17 |

Dimension | OD*Thk*L (10-114)*(0.4-10)*(100-15000)mm |

Manufacturing method | Cold rolled |

Condition | Annealed(M) |

Features | Light weight, excellent corrosion resistivity, strongly heat-resistance, high strength. |

Inspection | Ultrasonic testing, Hydrostatic testing, Flattening testing, visual surface inspection, Dimensional inspection, tensile properties inspection and Chemical elements analysis. |

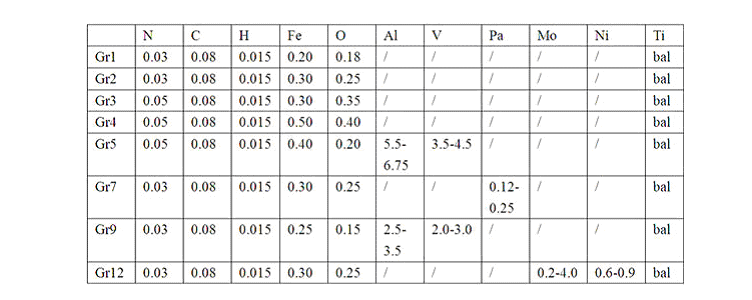

2.Chemical Requirements

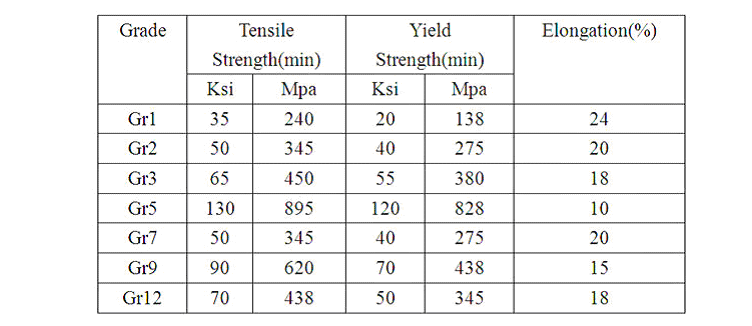

3.Tensile Properties