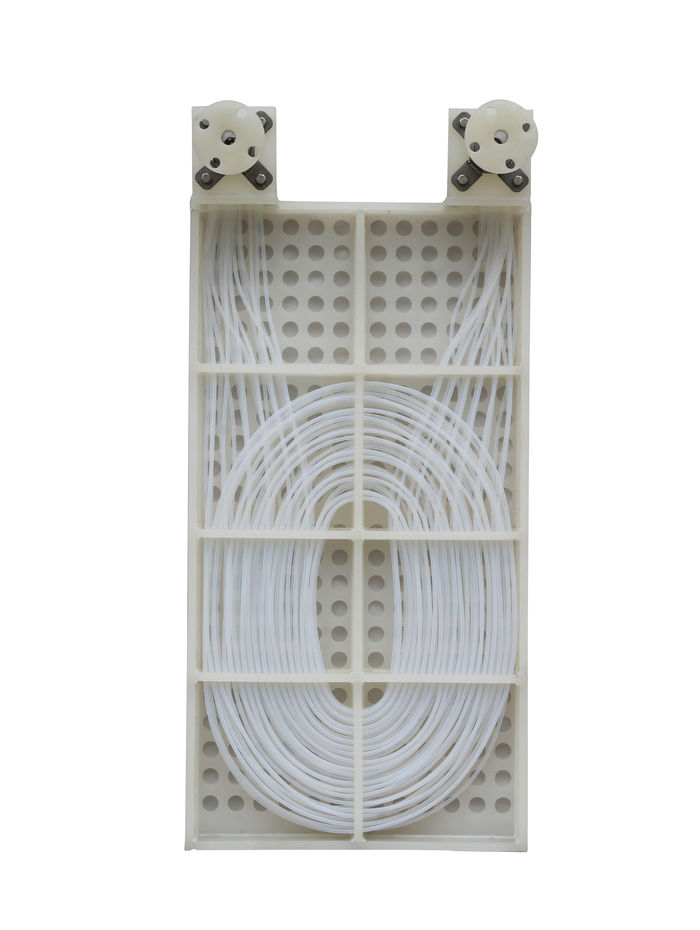

PTFE (Fluoropolymer) Immersion Coils

Teflon(Fluorpolymer) Heating and cooling coils |

Exchange area Sq.Ft | Connections Inch | Length In./mm | Width In./mm | Thickness In./mm | Model No. |

5.5 | 3/4 FNPT | 11.5(292) | 11.5(292) | 2(51) | XC-12-12 |

11 | 3/4 FNPT | 15.5(394) | 15.5(394) | 2(51) | XC-16-16 |

16.5 | 3/4 FNPT | 17.5(445) | 17.5(445) | 2.36(60) | XC-18-18 |

22 | 3/4 FNPT | 19.7(500) | 15.7(400) | 2.36(60) | XC-20-16 |

27.5 | 3/4 FNPT | 19.7(500) | 19.7(500) | 2.36(60) | XC-20-20 |

33 | 3/4 FNPT | 23.5(597) | 23.5(597) | 2.36(60) | XC-24-24 |

38.5 | 3/4 FNPT | 27.5(700) | 23.5(597) | 2.36(60) | XC-28-24 |

44 | 3/4 FNPT | 27.5(700) | 27.5(700) | 2.76(70) | XC-28-28 |

49.5 | 3/4 FNPT | 31.5(800) | 31.5(800) | 2.76(70) | XC-32-32 |

55 | 3/4 FNPT | 33.9(860) | 33.9(860) | 2.76(70) | XC-34-34 |

60.5 | 1 FNPT | 35.5(900) | 31.5(800) | 2.76(70) | XC-36-32 |

66 | 1 FNPT | 35.5(900) | 33.9(860) | 2.76(70) | XC-36-34 |

71.5 | 1 FNPT | 35.5(900) | 35.5(900) | 2.76(70) | XC-36-36 |

77 | 1 FNPT | 39.5(1000) | 33.9(860) | 3.15(80) | XC-40-34 |

83.5 | 1 FNPT | 39.5(1000) | 35.5(900) | 3.15(80) | XC-40-36 |

89 | 1 FNPT | 39.5(1000) | 39.5(1000) | 3.15(80) | XC-40-40 |

94.5 | 1 FNPT | 39.5(1000) | 39.5(1000) | 3.15(80) | XC-41-41 |

99 | 1-1/2 FNPT | 43.3(1100) | 39.5(1000) | 3.15(80) | XC-43-40 |

104 | 1-1/2 FNPT | 43.3(1100) | 39.5(1000) | 3.54(90) | XC-44-40 |

110 | 1-1/2 FNPT | 45.3(1150) | 39.5(1000) | 3.54(90) | XC-45-40 |

115 | 1-1/2 FNPT | 47.2(1200) | 39.5(1000) | 3.54(90) | XC-47-40 |

120 | 1-1/2 FNPT | 47.2(1200) | 39.5(1000) | 3.54(90) | XC-48-41 |

Materials of Construction

Our materials of construction for the Immersion Coil Heat Exchanger consists of either polypropylene, PVDF, or PTFE for the frame, and either FEP, PFA, or PTFE for the tubing. Custom designs may include other fluoropolymer materials such as ETFE, ECTFE or PCTFE.

Advantages

The advantages of our heat exchanger products over alternative designs include:

Low operating cost - The operating cost includes maintenance such as inspection, cleaning, downtime, and repair. This is primarily due to the relatively simple design that involves no plastic welding joints

No weld joints - Unlike metals that are subject to more rapid degradation under aggressive pickle bath conditions, Fluorotherm™’s heat exchangers withstand aggressiveness

Off the shelf repair kits - In case of an unlikely event of accidental tube damage, these kits enable a quick repair of the tubing

No tube bundling - The strong tubing coils are optimally spaced so acid flow and therefore heat transfer is maintained without fouling.

Constant operating efficiency - Fluoropolymers such as PTFE, FEP or PFA, are inherently “non-stick”, so fouling by scale deposition is minimized, assuring a constant operating efficiency that does not decrease over time. No other material, except natural diamond, inhibits sticking of the pickle bath particulates more than fluoropolymers

H2 TM Conductive Immersion Coil Heat Exchangers

Precise Heater™ manufactures H2 conductive tubing coil heat exchangers for use in restricted spaces in new and retrofit applications. This product provides between 2.3 to 2.7-times the heat transfer capability of clear, natural tubing coils. The heat transfer rate is similar to steel without the corrosion attack susceptibility. It is also used in baths where electrical static discharge is a major concern. This product has undergone several iterations of improvement in properties and is unique to Fluorotherm™’s line of heat exchanger offerings.

Hybrid Heat Exchangers

Precise Heater's hybrid frame heat exchangers were made specially for ultrapure and aggressive chemical heating and cooling. This new product combines the best components and design geometry for efficient heat transfer. The design, evolved from decades of field experience, is driven by the need to inhibit particulate settling on, and fouling of heat transfer surfaces. These particles (sludge and precipitates) fall out from the chemical reactions that occur during metal treatment in mineral acids, in the form of oxides, sulfates, chlorides, phosphates and other materials.